For years, EPR compliance in India felt manageable. Producers registered, filed returns once or twice a year, and moved on. That comfort is disappearing fast. In 2025, many businesses experienced something new—automated portal alerts, rejected certificates, delayed approvals, and compliance queries without warning.

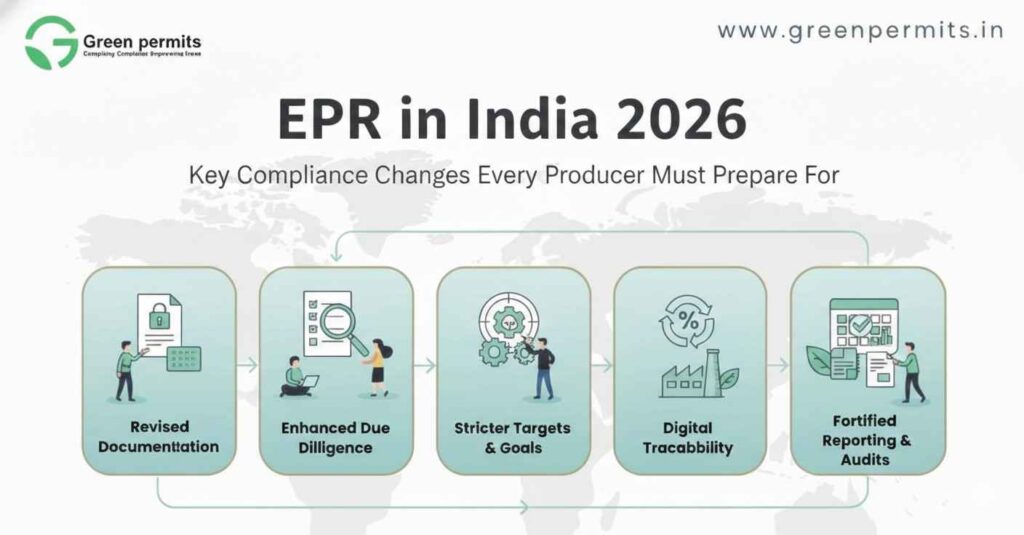

As India enters 2026, EPR has shifted from a passive obligation to an active control system. Producers who prepare early will operate smoothly. Those who don’t may face interruptions that affect sales, imports, and even product launches.

This guide explains what’s changing, how enforcement is evolving, and what producers should do now to stay ahead.

EPR was introduced to build accountability into waste management. Initially, enforcement focused on awareness and onboarding. That stage is now complete.

By 2026, regulators expect predictable, accurate, and continuous compliance from producers.

This maturity phase means:

What this evolution means for businesses:

EPR is now treated closer to GST or customs compliance than an environmental formality.

Many producers ask why enforcement feels sudden. The reality is that regulatory systems are now ready, not rushed.

The past few years were spent building portals, onboarding recyclers, standardizing certificates, and aligning rules across waste streams. With these systems in place, expectations have increased.

Why 2026 matters specifically:

For producers, this means past underreporting or casual filings are easier to detect.

Contrary to popular belief, the biggest risk is not new regulations—it is misalignment with existing ones.

Most enforcement actions arise from data mismatches rather than missing registrations.

Key changes producers are experiencing:

In simple terms, EPR compliance is becoming algorithm-driven.

Earlier, compliance officers manually reviewed filings and issued clarifications. That process does not scale for a national EPR system covering thousands of producers.

Digital enforcement reduces subjectivity and increases speed.

How enforcement now works in practice:

This system favors producers who maintain clean, timely records—and penalizes those who rely on last-minute fixes.

One of the biggest compliance challenges is overlapping EPR obligations. Many producers do not operate in a single category.

For example, an EV manufacturer may fall under:

Each category has different logic, timelines, and targets.

Why this matters operationally:

Successful producers treat EPR as a portfolio, not isolated tasks.

| EPR Category | Covered Entities | Core Focus | Risk Exposure |

|---|---|---|---|

| Plastic Waste EPR | PIBOs, Importers | Packaging recovery | Compensation & listing |

| Battery Waste EPR | Battery & EV Players | Metal recovery | Certificate deficit |

| E-Waste EPR | Electronics Producers | Product-wise recycling | Portal suspension |

| Tyre EPR | Tyre Producers | Recovery targets | Sales disruption |

| ELV EPR | Vehicle Producers | Steel recycling | Registration impact |

Interpretation:

Compliance failure in one category often draws scrutiny across others.

Most compliance failures are not deliberate. They happen because EPR is treated as a documentation exercise instead of a data discipline.

Risk builds quietly until enforcement action begins.

Commonly overlooked areas:

These gaps often surface during audits or renewals—when correction is expensive.

| Gap Area | Regulatory Response | Business Outcome |

|---|---|---|

| Late filings | Automated flags | Temporary suspension |

| Certificate shortfall | Target carry-forward | Higher future cost |

| Invalid recycler | Certificate rejection | Re-purchase required |

| Inconsistent data | Audit trigger | Time & cost drain |

| Lapsed registration | Portal lock | Sales interruption |

Business reality:

EPR mistakes now affect cash flow, timelines, and leadership bandwidth.

A mid-sized consumer electronics brand expanded aggressively in FY 2024–25. EPR filings were completed using previous-year assumptions. No one noticed the mismatch until the portal calculated new targets.

The outcome:

Nothing illegal occurred—but planning lagged behind growth.

Leading producers are changing how they manage compliance—not just who manages it.

They integrate EPR into business planning.

What smarter preparation looks like:

This reduces volatility and improves predictability.

Penalties are only one part of the cost. The real damage often comes from disruption.

Delayed preparation leads to:

Early preparation spreads cost evenly and avoids shocks.

As EPR systems mature, compliance history becomes a signal of reliability.

Well-maintained records help with:

In contrast, repeated errors increase scrutiny.

EPR is quietly becoming a trust indicator.

By 2026, EPR compliance in India will separate reactive businesses from prepared ones. Those who embed compliance into operations will move faster and face fewer surprises. Those who wait will spend more time fixing than growing.

The difference is not resources—it is readiness.

📞 +91 78350 06182

📧 wecare@greenpermits.in

No, enforcement is becoming more systematic and consistent.

No, size does not exempt compliance obligations.

Targets are defined but depend on accurate sales reporting.

Yes, import volumes directly impact EPR obligations.

Repeated non-compliance increases audit and penalty risk.