Intrinsicly evisculate emerging cutting edge scenarios redefine future-proof e-markets demand line

Gallery Posts

Working Hours

| Mone - Fri: | 09:00 - 06:00 |

|---|---|

| Saturday: | 09:00 - 12:00 |

| Sunnday | 09:00 - 04:00 |

| Monday | 09:00 - 05:00 |

Intrinsicly evisculate emerging cutting edge scenarios redefine future-proof e-markets demand line

| Mone - Fri: | 09:00 - 06:00 |

|---|---|

| Saturday: | 09:00 - 12:00 |

| Sunnday | 09:00 - 04:00 |

| Monday | 09:00 - 05:00 |

India is racing toward its 20% ethanol blending target by 2025, making distillery projects one of the most promising opportunities in the renewable fuel sector. However, before setting up an ethanol unit, businesses must secure environmental clearance (EC) from authorities such as the Ministry of Environment, Forest and Climate Change (MoEFCC) and the respective State Pollution Control Boards (SPCBs).

In 2023, India produced more than 600 crore litres of ethanol, a 45% increase over 2022. Despite the surge, many projects face delays due to incomplete compliance. This article explains the environmental clearance process for ethanol plants in India with recent data, step-by-step guidance, and a practical case study.

Environmental clearance is more than a regulatory requirement. It provides the framework for sustainable operations and safeguards against long-term risks. Obtaining EC ensures that ethanol plants:

Operating without EC exposes businesses to legal penalties, shutdown orders, and loss of access to government incentives.

Ethanol projects must comply with multiple authorities. Each plays a distinct role:

Together, these regulators form the approval chain every ethanol project must navigate.

India’s ethanol sector has expanded rapidly under government blending programs. Key highlights include:

These figures demonstrate the strong demand but also highlight the importance of timely approvals.

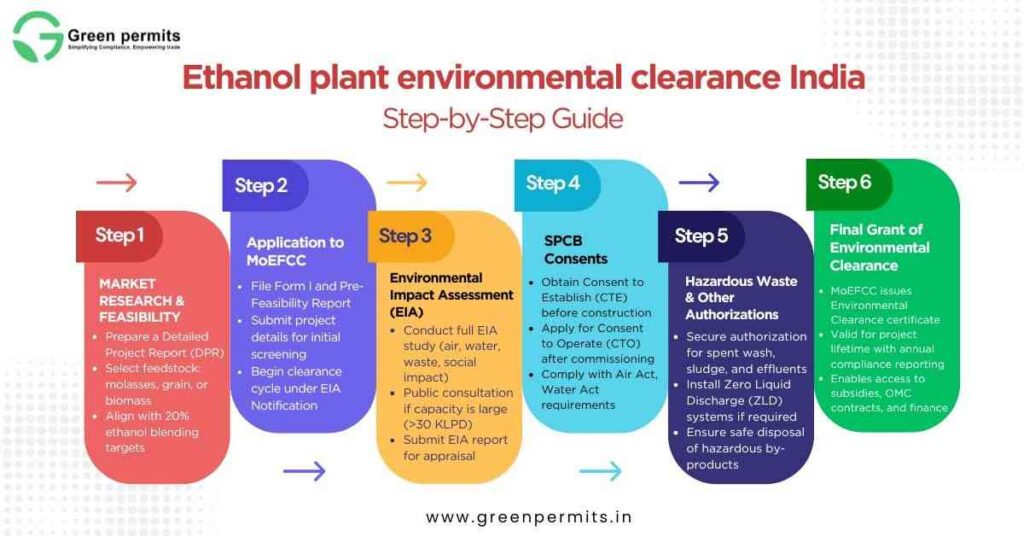

The environmental clearance process involves several interlinked steps.

Develop a Detailed Project Report (DPR) covering feedstock selection (molasses, grain, or biomass), proposed capacity in KLPD, location zoning, and financial projections.

Submit Form I and a Pre-Feasibility Report (PFR) to the MoEFCC to initiate the clearance process.

Carry out an EIA study covering water consumption, effluent management, emissions, solid waste handling, and social impact. Public consultations may be required for larger projects.

Apply to the State Pollution Control Board for Consent to Establish (CTE). Once the plant is ready for operations, apply for Consent to Operate (CTO).

Obtain authorization for handling sludge, spent wash, and other by-products under the Hazardous Waste Management Rules.

After MoEFCC evaluation and SPCB consents, environmental clearance is granted. The clearance is valid throughout the project life but requires regular compliance reporting.

Before breaking ground, ethanol projects must complete the following:

| Parameter | Molasses-Based | Grain-Based | 2G (Biomass-Based) |

|---|---|---|---|

| Raw Material | Sugarcane molasses | Maize, rice, surplus grain | Rice straw, bagasse, crop residue |

| CapEx (60 KLPD plant) | ₹90–120 Cr | ₹120–150 Cr | ₹250–400 Cr |

| Opex (per litre) | ₹30–35 | ₹32–38 | ₹40–50 |

| EC Requirement | EIA + SPCB consents | EIA + SPCB consents | Stringent EIA + MoEFCC clearance |

| Payback Period | 4–5 years | 4 years (with OMC contracts) | 6–8 years |

A grain mill in Uttar Pradesh recently commissioned a 60 KLPD grain-based ethanol unit with an investment of ₹150 crore. By securing environmental clearance and state-level approvals early, the unit signed a long-term contract with OMCs. The project achieved payback in four years while adopting zero-liquid discharge technology, which also improved regulatory goodwill and financing terms.

Environmental clearance is increasingly tied to sustainability performance. Investors and regulators focus on:

Projects that integrate ESG considerations often receive faster approvals and access to lower-cost financing.

Typically 6 to 12 months, depending on EIA review and SPCB response times.

The SPCB issues CTE and CTO, which are mandatory to begin construction and operations.

Yes. Projects above 30 KLPD must undergo a detailed EIA. Smaller plants may receive exemptions but still need SPCB approvals.

Units may face closure, fines, and ineligibility for subsidies and OMC contracts.

Yes. Without EC, ethanol projects cannot access soft loans, viability gap funding, or government procurement schemes.

India’s ethanol mission presents exceptional opportunities, but success depends on timely environmental clearance. MoEFCC approvals, SPCB consents, and related certifications are crucial for both compliance and business growth.

Green Permits specializes in guiding ethanol projects through the entire compliance journey — from feasibility and DPR preparation to securing MoEFCC, SPCB, and BIS approvals.

Email: wecare@greenpermits.in

Call: +91-78350 06182