Ravi runs a mid-sized manufacturing unit supplying components to EV companies in Pune. Over the last two years, he noticed something unusual. Enquiries for handling used EV batteries were increasing faster than enquiries for new components. Everyone he spoke to mentioned lithium, cobalt, and black mass margins.

When Ravi explored the recycling business seriously, the excitement quickly gave way to confusion. Multiple approvals, fire safety questions, CPCB registrations, and unclear timelines made him realize this wasn’t just another manufacturing expansion. It was a compliance-heavy business with real operational risks.

If you are considering lithium-ion battery recycling in India, this guide will help you understand where the opportunity is real and where businesses quietly lose money.

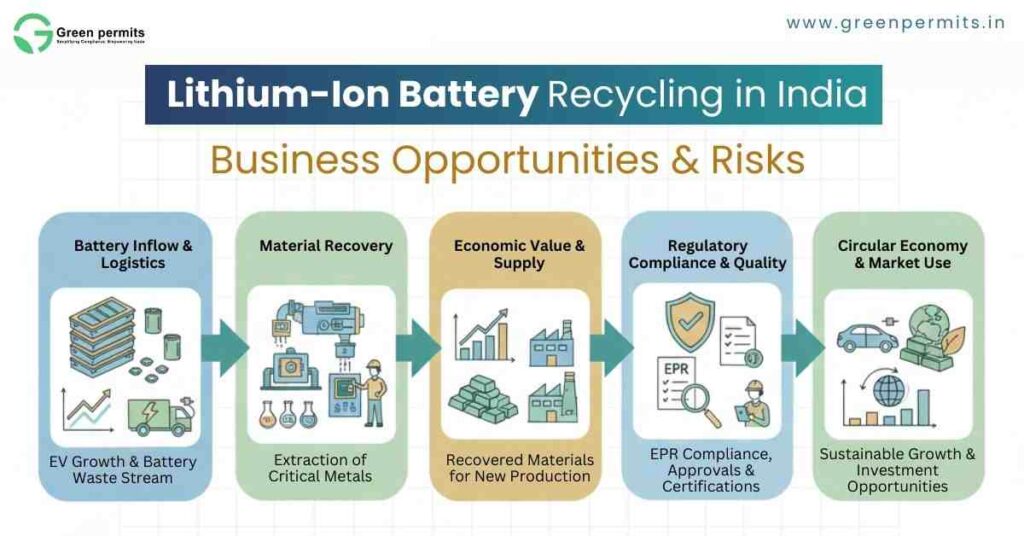

India’s shift toward electric mobility and energy storage has created a new waste stream that cannot be ignored. Lithium-ion batteries have a limited lifecycle, and their disposal is now a regulatory responsibility rather than a choice.

For businesses, this creates a unique opportunity — recycling is no longer optional, it is mandatory.

Before looking at profits, it’s important to understand why demand is structurally strong:

| Indicator | Business Insight |

|---|---|

| EV adoption | Creating predictable future battery waste |

| Battery imports | Increasing pressure to recover metals locally |

| Recycling demand | Driven by compliance, not just market pricing |

| Metal recovery | Secondary raw materials reduce import exposure |

What this means for businesses:

Recycling demand does not disappear during market downturns. As long as batteries are sold, recycling obligations continue.

Many first-time investors assume profits come only from selling recovered metals. In reality, lithium-ion battery recycling in India works on two parallel revenue engines.

Most compliant recyclers earn through:

EPR certificates are often underestimated. For many recyclers, they provide more predictable income than metal price movements.

Additional income sources include:

Important business insight:

Plants designed only for metal recovery often struggle with cash flow. Plants aligned with EPR demand stay operationally stable.

Lithium-ion battery recycling is not a “set up and start” business. It operates entirely within a regulated framework.

The Battery Waste Management Rules define who can operate, how recycling must be done, and how accountability is tracked.

A recycler typically interacts with:

| Approval | Authority | Business Impact |

|---|---|---|

| Recycler Registration | SPCB / CPCB | Legal recognition |

| Consent to Establish | SPCB | Approval before plant setup |

| Consent to Operate | SPCB | Permission to start operations |

| Hazardous Waste Authorization | SPCB | Legal battery handling |

| Fire Safety Clearance | Local Authority | Risk mitigation |

| EPR Portal Registration | CPCB | Certificate generation |

Business reality:

Missing even one approval can freeze operations or block EPR certificate generation.

Understanding the approval sequence saves both time and money.

This stage is often ignored and later regretted:

Mistakes here are difficult to reverse later.

This involves:

Incomplete submissions are the most common reason for repeated objections.

Once approvals are granted:

Hidden risk:

Many businesses invest in machinery before approvals, only to discover compliance gaps that delay operations for months.

Lithium-ion battery recycling failures are rarely technical. They are usually compliance-driven.

A recycler invested heavily in machinery but delayed fire safety compliance. A routine inspection halted operations for months, while EMI and overheads continued. The business survived, but profitability took years to recover.

| Non-Compliance Area | Business Consequence |

|---|---|

| Operating without registration | Closure and penalties |

| Incorrect EPR reporting | Certificate suspension |

| Unsafe storage | Environmental compensation |

| Fire safety lapses | License cancellation |

Business takeaway:

Penalties affect not just finances but also trust with EV manufacturers and producers.

Yes — but only when compliance is built into the business model.

Businesses that complete registrations before commissioning experience:

Compliance, when planned early, becomes a cost-saving strategy rather than a burden.

Lithium-ion battery recycling in India is a long-term opportunity, not a shortcut business. The companies that succeed are those that treat compliance as part of infrastructure, not paperwork.

Early planning, correct approvals, and structured EPR strategies protect margins, timelines, and reputation.

📞 +91 78350 06182

📧 wecare@greenpermits.in

Book a Consultation with Green Permits

We help businesses with Battery Waste Management compliance, CPCB registrations, EPR strategy, and recycling plant approvals — end to end.