A solar importer from Ahmedabad once called us just two days before his shipment reached Mundra Port. Payments were cleared. Dealers were ready. Installation contracts were signed.

But customs asked one question: “Where is the BIS CRS registration?”

The shipment was held. Demurrage charges started accumulating daily. The EPC client began asking uncomfortable questions. What looked like a simple compliance formality turned into a business disruption costing lakhs.

If you are manufacturing or importing modules, BIS Certification for Solar Panels in India is not paperwork — it is market access permission.

India’s renewable energy sector is growing aggressively, and the government wants quality, safety, and performance assurance in the solar ecosystem. To control substandard imports and ensure reliability, certain solar photovoltaic (PV) products are brought under the Compulsory Registration Scheme (CRS) of BIS.

This means no manufacturer — domestic or foreign — can legally sell notified solar modules in India without valid BIS registration. Enforcement is active at customs, state departments, and project tender levels.

For businesses, this directly impacts operations and revenue stability.

When compliance is ignored, the consequence is rarely just a warning — it usually affects shipments, payments, and project timelines.

The Compulsory Registration Scheme (CRS) is the route under which solar panels are registered with BIS. Unlike traditional ISI certification, CRS focuses on product testing and registration based on conformity to notified Indian Standards.

CRS is product-specific. Registration is granted for a specific brand, specific manufacturing location, and specific product category. If any of these change, fresh compliance may be required.

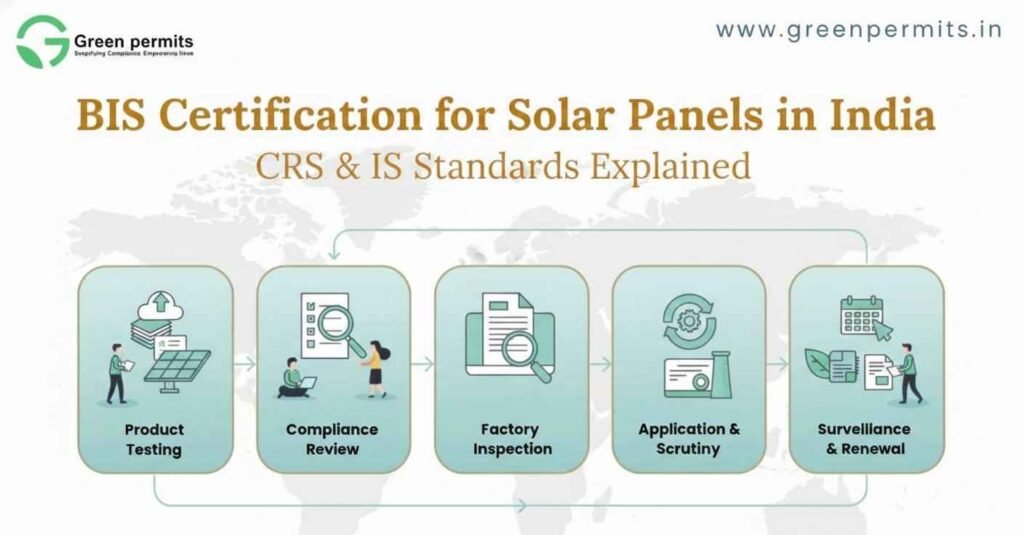

Businesses often assume CRS is a one-time online form. In reality, it is a structured compliance process involving lab testing, documentation validation, and regulatory scrutiny.

CRS applies to:

Foreign manufacturers must appoint an Authorized Indian Representative (AIR), who becomes legally responsible for compliance within India.

Key characteristics of CRS for solar panels:

A minor documentation mismatch can delay approval significantly.

Solar panels are regulated under specific Indian Standards that are harmonized with international IEC standards. Selecting the correct standard is critical because incorrect mapping is one of the most common reasons for rejection.

Different technologies require different standards. Applying under the wrong category can restart the process entirely.

| Solar Product Type | Applicable IS Standard | Purpose |

|---|---|---|

| Crystalline Silicon PV Modules | IS 14286 | Performance Qualification |

| Thin-Film PV Modules | IS 16077 | Design Qualification |

| Safety Requirements | IS 61730 (Part 1 & 2) | Electrical & Fire Safety |

These standards evaluate:

For manufacturers, this means product design, bill of materials, and production quality must align with testing parameters before samples are sent to labs.

Incorrect sample submission can result in:

Planning standard mapping at the product development stage reduces compliance risk later.

Many businesses think registration starts when the shipment is ready. In reality, it should begin months earlier.

The process requires coordination between manufacturing, quality control, documentation teams, and compliance advisors.

The broad journey looks simple, but execution precision determines approval speed.

The process involves:

Important documentation typically includes:

Even small inconsistencies — such as spelling variations in brand name — can trigger clarification requests.

One of the biggest misconceptions in the market is the timeline expectation. Many assume certification is quick. In practice, lab scheduling, documentation preparation, and BIS scrutiny take time.

Testing itself is technical and cannot be rushed without risk of failure.

A realistic planning window should include:

In practical terms, businesses should plan for 6–10 weeks minimum.

If products are already in production and certification is not initiated, shipment schedules can collapse.

Early planning prevents:

Compliance failures rarely happen intentionally. They usually occur due to assumption or poor planning.

A common situation we see: An importer assumes the overseas manufacturer’s previous BIS registration is still valid. The shipment arrives. The registration has expired.

Consequences include:

In competitive EPC markets, delay equals financial loss and reputational damage.

There is frequent confusion between CRS and ISI certification. For solar PV modules, CRS is the applicable compliance route.

CRS focuses on:

ISI certification, on the other hand, involves factory inspection and marking requirements.

Understanding this distinction avoids applying under the wrong scheme and wasting time.

BIS CRS registration is granted for a defined validity period. Businesses often focus only on initial approval and ignore renewal tracking.

If registration expires:

Smart compliance management includes maintaining a renewal calendar and document readiness well before expiry.

BIS compliance does not operate in isolation. Solar businesses must also evaluate regulatory intersections.

Depending on the business model, additional regulatory checkpoints may include:

A structured compliance roadmap ensures there are no surprises from parallel regulatory frameworks.

Most rejections are preventable. They arise from avoidable oversight.

Frequent mistakes include:

Conducting a pre-submission compliance audit significantly reduces rejection risk.

Solar manufacturing and import businesses operate on tight margins and delivery timelines. Compliance should be aligned with production planning.

A proactive approach includes:

Early registration saves cost, time, and operational stress.

India’s solar market offers enormous growth opportunity. But regulatory enforcement is structured and increasingly strict.

Ignoring BIS Certification for Solar Panels in India can result in:

Compliance is not an expense — it is business continuity protection.

If you are planning to manufacture or import solar panels, structured regulatory planning is essential.

📞 +91 78350 06182

📧 wecare@greenpermits.in