- Home

- About Us

- Services

- Resources

- Contact Us

- Home

- About Us

- Services

- Resources

- Contact Us

Last year, the operations head at Arvia GreenPower Pvt. Ltd. visited three different battery recycling plants across Maharashtra. What he expected to see were high-tech hydrometallurgical labs and complex chemical reactors. Instead, he discovered something surprising — the facilities that were actually making money consistently were not the big refiners at all.

They were small lithium battery dismantling units operating out of 2,000–3,000 sq ft industrial sheds, focusing on pre-processing only — no chemical extraction, no effluent treatment headaches, no ₹50 crore investment. They were simply dismantling EV and ESS batteries, safely generating black mass, and selling it to licensed refiners who were hungry for ready-to-process material.

This guide explains how you can build such a dismantling + pre-processing facility in India, even if you’re beginning from scratch.

A lithium battery dismantling plant is not just a cheaper version of a recycling facility — it’s a different business model altogether. Understanding its unique benefits helps new investors avoid over-investing in heavy refining infrastructure.

Dismantling requires:

Refining requires:

Most new entrants simply cannot justify the heavy technical requirements of refining.

India’s refiners face a clear bottleneck:

Refining lines sit idle because very few dismantlers supply stable volumes of clean black mass.

This gap creates an ideal entry point for dismantling units.

Mechanical separation carries lower environmental risk.

Scaling dismantling is simply adding more workers or semi-automated equipment, instead of re-engineering an entire chemical line.

Since dismantling avoids chemical processes, state pollution boards typically process approvals faster than full recycling units.

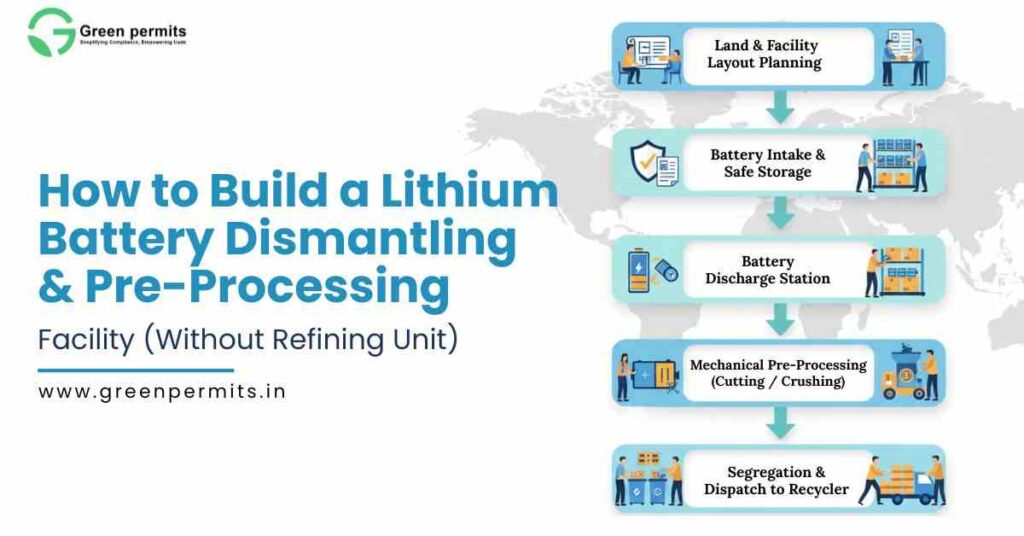

Most dismantling operations follow the same broad process, but efficiency, safety, and compliance depend entirely on how well each step is designed.

This step determines the safety of your entire facility. Poor incoming inspection is the number one cause of fires in small dismantling workshops.

Incoming quality determines:

A well-structured receiving area is the foundation of operational safety.

Before a battery pack is opened, it must be neutralized electrically. This protects workers and equipment.

A disciplined discharge protocol significantly reduces insurance premiums and operational disruptions.

This is where trained technicians carefully open the battery pack structure without causing sparks or structural damage.

This is labour-intensive work. Workers need skill, not degrees. Proper training and SOPs matter more than advanced qualifications.

Depending on your investment level, you may run:

For low-volume units, workers directly open cylindrical/pouch cells to extract foil structures.

Includes:

Mechanical separation generates your main revenue stream — black mass — which refiners buy at attractive rates.

Black mass should be stored in:

It is considered a hazardous recyclable material, so documentation must be clean and traceable.

Below is an expanded machinery overview based on small, medium, and semi-automated setups.

| Equipment | Function | Approx Cost |

|---|---|---|

| Discharge Rack | Removes charge | ₹1–4 lakh |

| Pack Opening Tool Kit | Manual opening | ₹30,000–₹1 lakh |

| Fume Hood | Adhesive fumes | ₹50,000–₹1.5 lakh |

| Fire Suppression System | Safety | ₹1.5–₹4 lakh |

| Workbenches & Insulation Mats | Manual dismantling | ₹50,000–₹1 lakh |

| Equipment | Function | Approx Cost |

|---|---|---|

| Small Shredder | Cell shredding | ₹4–₹15 lakh |

| Sieving Machine | Powder sorting | ₹1–₹3 lakh |

| Magnetic Separator | Ferrous removal | ₹50,000–₹2 lakh |

| Air Classifier | Foil/plastic separation | ₹3–₹10 lakh |

| Equipment | Function |

|---|---|

| Inert-atmosphere Shredder | Works under nitrogen; safer for EV packs |

| Multi-stage Sieving Line | High purity black mass |

| Robotic Pack Dismantlers | Rare, expensive but scalable |

Most new entrants stay within the first two categories.

A practical dismantling unit does not require a massive area.

| Zone | Purpose | Area Required |

|---|---|---|

| Receiving + Testing Area | Initial inspection | 200–400 sq ft |

| DDD Zone | Hazardous battery isolation | 100–200 sq ft |

| Discharge Room | Safe neutralization | 150–300 sq ft |

| Pack Opening | Mechanical dismantling | 250–500 sq ft |

| Shredding Area | Mechanical processing | 300–800 sq ft |

| Black Mass Storage | Secure storage | 100–150 sq ft |

| Admin & Compliance Desk | Documentation | 100 sq ft |

A fully functional lithium battery dismantling plant can operate smoothly within 1,500–3,000 sq ft.

A dismantling + pre-processing unit falls under the Recycler category under current Indian rules. While refining requires heavy permissions, dismantling is far simpler.

Refiners will not buy black mass from unregistered dismantlers.

Also, non-compliance can pause your business overnight.

Below is an expanded economics table for real-world planning.

| Material | Market Price (Approx.) | Notes |

|---|---|---|

| Black Mass | ₹90–₹250/kg | Depends on chemistry (NMC, LFP, LCO) |

| Copper Foil | ₹480–₹620/kg | High and stable demand |

| Aluminium Foil | ₹130–₹190/kg | Consistent scrap market |

| Steel Parts | ₹40–₹55/kg | Basic scrap |

| Plastics | ₹8–₹22/kg | Low margin but significant volume |

Even without refining, dismantling offers strong profitability because you convert an unusable battery pack into four high-demand materials.

A small unit in Ahmedabad began operations with just:

They focused purely on EV battery packs from a local fleet aggregator.

Their only outputs were modules and cells, which were sold to a larger recycler.

Within 6 months:

By month 9, they reinvested profits into a small mechanical shredder and sieving line — doubling their margins without external funding.

A single un-discharged cell can ignite foam, plastic, or metal shavings.

Missing batch logs or vendor details can lead to registration suspension.

Adhesive fumes from opening packs can cause worker health issues.

Mixing damaged batteries with healthy ones is a critical error.

If purity is poor, refiners will discount your material heavily.

Starting a lithium battery dismantling plant is one of the smartest ways to enter India’s rapidly expanding energy-storage circular economy. It combines manageable compliance, low investment, fast payback, and strong demand from refiners.

By focusing on dismantling and pre-processing only, you avoid the complexity of chemical recycling while still building a scalable, profitable, and future-proof business.

📞 +91 78350 06182

📧 wecare@greenpermits.in

Book a Consultation with Green Permits

A 1 TPD plant typically needs 15,000–20,000 sq ft including shredding, hydrometallurgy, and ETP zones.

Key machines include an inert shredder, density separator, sieves, hydromet reactors, filter press, and a multi-stage ETP.

Yes, lithium-ion batteries must be shredded under nitrogen or controlled atmosphere to prevent fire risks.

Black mass is a powder mixture containing lithium, cobalt, nickel, manganese, and graphite extracted after shredding.

You need SPCB CTO/CTE, Hazardous Waste Authorization, and recycler registration on the CPCB/BWM portal.