- Home

- About Us

- Services

- Resources

- Contact Us

- Home

- About Us

- Services

- Resources

- Contact Us

When “VoltEdge Renewables,” a Mumbai-based EV spare parts supplier, decided to launch its own lithium battery recycling unit, the team expected the process to be mainly about technology and machinery.

But the first real roadblock came when they applied for a Pollution NOC. Their application was pushed back because the lithium cell storage room lacked a fire-rated partition wall and proper ventilation.

This one oversight delayed their entire project by nearly 90 days.

This is what most founders face—technology is rarely the biggest challenge, licenses are.

That’s why this guide clearly explains every license and clearance required for a lithium battery recycling plant in India, and the sequence in which they should be obtained, so you avoid delays, penalties, and compliance surprises.

Lithium battery recycling is classified as a specialized hazardous waste operation. It involves dismantling battery packs, shredding modules, and handling black mass that contains volatile metals. Because of these safety and environmental risks, India enforces a multi-layered licensing framework.

A recycling plant interacts with multiple laws at the same time:

Each license plays a specific role and ensures that your plant layout, machinery, storage areas, emission systems, and fire controls meet national standards.

Founders who understand the purpose of each clearance find it much easier to build investor confidence, survive inspections, and avoid shutdowns.

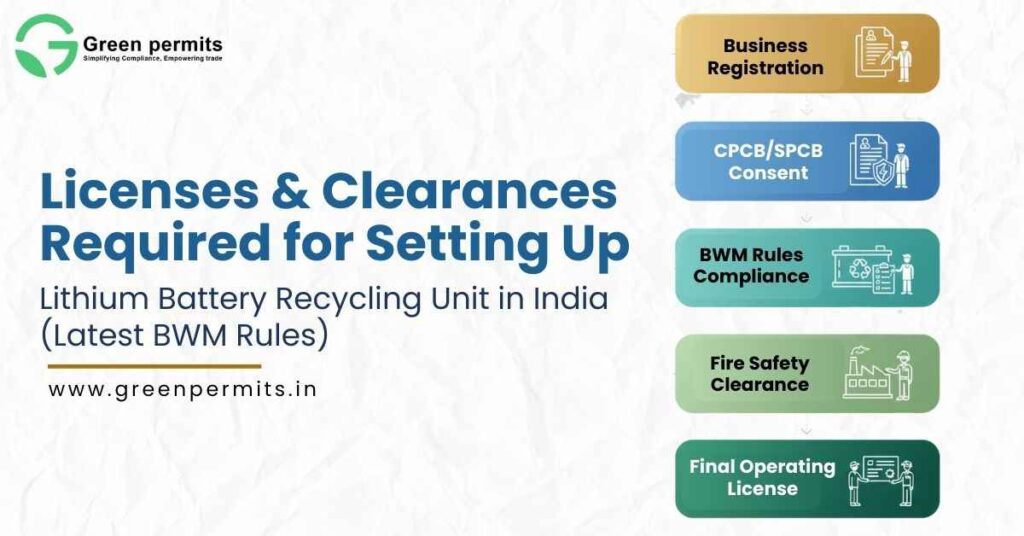

This sequence is the industry-standard roadmap used by experienced plant developers. Following this order prevents rejection and speeds up approvals.

Before approaching any pollution or safety authority, your entity must be legally recognized.

The government requires a valid business identity for traceability, environmental accountability, and liability.

All future licenses—SPCB, Fire, Factory Inspectorate—are issued in the company’s legal name.

Incomplete documentation here causes delays across the entire project.

Lithium battery recycling plants must operate only in approved industrial zones. States may have different zoning policies, so CLU becomes essential.

SPCB will not issue a Consent to Establish (CTE) if the land isn’t approved for industrial or hazardous waste operations.

This is the backbone of your licensing process. Regulators need full clarity on how your plant will operate.

Authorities rely on this document to judge the environmental and safety impact of your project. A weak or generic report leads to long scrutiny cycles.

This is the first major approval for your recycling plant.

You cannot build, install machinery, or even start construction without CTE.

15–30 working days depending on state workload.

A correct CTE makes all future approvals smoother. A wrong capacity, incorrect process description, or missing documents can set your project back months.

Once CTE is granted, you must seek approvals for plant construction, building layout, and worker safety.

Lithium battery recycling involves dismantling, crushing, and processing chemicals, which fall under hazardous operations. The Factory Inspector’s approval ensures you meet industrial safety standards.

Lithium battery fires spread rapidly and require specialized suppression systems. Fire departments evaluate whether your setup can control thermal runaway.

Most CTO applications get delayed due to fire non-compliance. Fixing fire issues after construction is often costly and time-consuming.

Since waste lithium batteries are classified as hazardous, this authorization is compulsory.

Without this authorization, recycling of any kind is illegal, even if you have a Pollution NOC.

CTO is the final environmental clearance that legally allows you to run the recycling plant.

Typically ranges between 1–5 years depending on state.

CTO is the gateway to CPCB registration and EPR certificate generation.

After CTO, you can apply for national-level registration as a lithium battery recycler.

Without CPCB registration, you cannot issue EPR certificates.

This is the license that officially recognizes you as a registered battery recycler in India.

After registration, you must report:

This is what enables producers to purchase certificates from you.

EPR certificate revenue is often the main profit source for recyclers. Compliance accuracy ensures uninterrupted certificate trading.

Depending on plant size and process technology, you may also need:

These vary by state but can significantly impact project timelines.

| License | Issued By | Purpose | Stage |

|---|---|---|---|

| Company Registration | MCA | Legal identity | Pre-setup |

| Land Use / CLU | Town Planning Dept | Industrial land approval | Before CTE |

| CTE | SPCB | Permission to build | Before construction |

| Factory License | Labour Dept | Worker safety compliance | During civil setup |

| Fire NOC | Local Fire Dept | Fire and explosion safety | Before CTO |

| Hazardous Waste Authorization | SPCB | Permission to handle waste | Pre-CTO |

| CTO | SPCB | Permission to operate | Pre-CPCB |

| CPCB Recycler Registration | CPCB | National-level recognition | Post-CTO |

| EPR Reporting Access | CPCB | Certificate trading | After registration |

| Clearance | Cost Range | Duration | Notes |

|---|---|---|---|

| CTE | ₹15,000–₹1.5 lakh | 15–30 days | Based on category |

| CTO | ₹20,000–₹2 lakh | 20–40 days | Inspection heavy |

| Fire NOC | ₹10,000–₹1 lakh | 15–30 days | Critical for lithium |

| CPCB Registration | ₹10,000–₹40,000 | 15 days | Valid for 5 years |

| Factory License | State-dependent | 30–60 days | Layout-intensive |

When founders rush the process, they usually face:

In severe cases, a plant can be temporarily shut until compliance gaps are fixed.

Understanding the risks upfront prevents financial loss and safeguards investor confidence.

Setting up a lithium battery recycling plant is a structured process. Success depends on following the correct order of approvals, planning fire safety early, and ensuring your project report matches your actual process.

When handled correctly, approvals move smoothly, EPR certificates start flowing, and the business becomes profitable from the first year.

When handled poorly, even strong investors lose confidence.

If you want a project roadmap that avoids unnecessary delays, expert regulatory support can make a meaningful difference.

If you want professional help with obtaining all licenses for a lithium battery recycling plant, the Green Permits team is ready to guide you.

📞 +91 78350 06182

📧 wecare@greenpermits.in

Book a Consultation with Green Permits

You need CTE, CTO, Hazardous Waste Authorization, Fire NOC, Factory License, and CPCB Recycler Registration.

Yes. Without CPCB registration, recyclers cannot legally operate or generate EPR certificates.

Typically 30–60 days, depending on the state, documentation quality, and plant category.

4. Do lithium battery recyclers need Hazardous Waste Authorization?

No. Fire NOC is mandatory because lithium batteries pose thermal runaway and fire risks.