- Home

- About Us

- Services

- Resources

- Contact Us

- Home

- About Us

- Services

- Resources

- Contact Us

A few months ago, a young entrepreneur from Hyderabad reached out to us. He had already purchased a 20,000 sq ft industrial plot, collected machinery quotations worth nearly ₹3 crore, and even hired a small technical team. But he still couldn’t finalize his plant layout.

Every machinery vendor suggested a completely different layout. His consultant insisted the shredding zone should be central. The machinery fabricator told him to place leaching tanks near the main gate for easy acid delivery. And his fire safety officer insisted that shredding should be moved to a separate block altogether.

He was stuck, overwhelmed, and losing money every month.

This is more common than you think. In battery recycling, the right layout determines compliance approvals, fire safety, operational efficiency, throughput, and even long-term scalability. Machinery alone doesn’t make a recycling plant — the layout does.

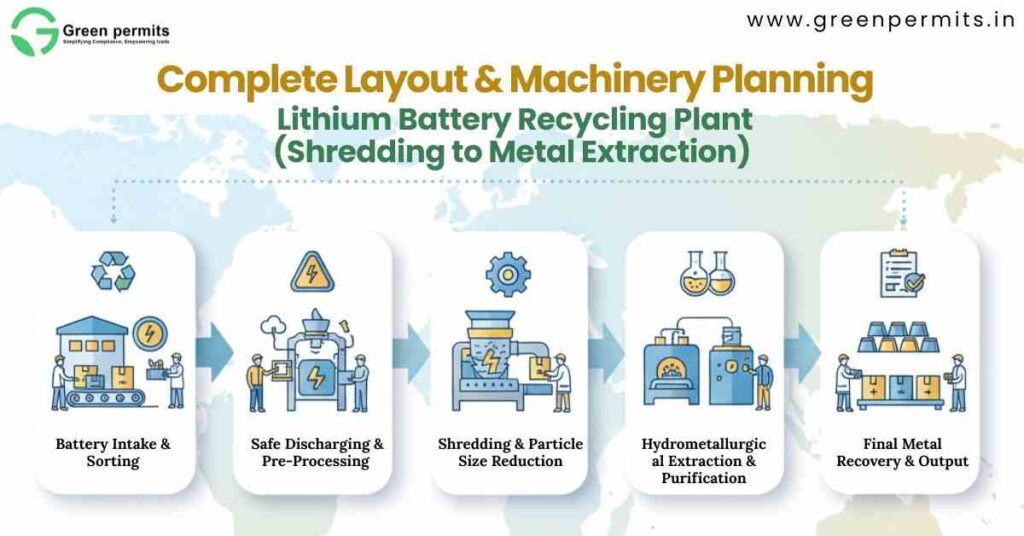

This guide demystifies how a lithium battery recycling plant should be designed, from battery receiving to metal extraction. Every section combines practical plant experience with regulatory expectations and modern engineering practices.

Most new recyclers assume “machinery first, layout later.” In reality, layout determines everything: fire risk, acid handling, nitrogen placement, worker safety, and even how clean your black mass output will be.

A well-designed layout ensures:

The entire plant’s performance — output quality, safety, compliance, and ROI — depends on physical design far more than on individual machines.

Before any recycling can start, batteries enter your receiving, inspection, and sorting zone. This is the first area inspectors examine — and the place where the majority of operational mistakes occur.

When a truck arrives, workers must:

Many plants try to pack these steps into one congested corner. This compromises safety and leads to confusion during inspections.

A well-designed pre-processing zone prevents delays and ensures smooth flow into dismantling.

This zone prepares batteries for shredding by safely removing casings and reducing charge. Most fire incidents in Indian recycling plants start here due to improper handling or inadequate ventilation.

Manual dismantling works best for variable scrap quality, mixed chemistries, or small volumes.

Automatic lines suit high volumes with consistent formats (EV or ESS packs), offering:

But automatic dismantlers need more space and higher power load, so layout must accommodate that.

Shredding is where chemical and mechanical forces combine. And this is where nearly all high-temperature reactions, sparks, and fires can occur. That’s why this zone requires the most thoughtful engineering.

Lithium reacts violently with oxygen. Without nitrogen or controlled atmosphere, the risk of fire is extremely high.

A poorly designed shredding zone can result in extended downtime, insurance issues, or even complete project shutdown.

After shredding, the material is a mix of metal foils, black mass, plastics, separators, and graphite dust. This zone refines the output before sending black mass to hydrometallurgy.

An efficient separation zone increases black mass purity and boosts hydromet recovery efficiency.

This is the revenue-generating core of the plant. Hydrometallurgy allows selective extraction and purification of metals from black mass. Designing this zone correctly is critical for both compliance and profitability.

Hydrometallurgy also requires an ETP next door to manage wastewater containing heavy metals.

This is one of the most inspected areas during government visits. It must be designed with foresight because changes later are expensive.

An ETP placed far away from the hydromet zone increases piping cost and maintenance issues. Ideal design keeps them close, yet safely segregated.

A high-performing plant typically follows this sequence:

Battery Receiving → Sorting → Discharge → Dismantling → Inert Shredding → Sieving → Magnetic & Density Separation → Black Mass Drying → Hydrometallurgy → Metal Extraction → ETP Treatment → Waste Storage → Final Product Packaging

This flow minimizes cross-contamination, increases productivity, and aligns with standard engineering practices.

| Machinery | Capacity | Cost (₹ Lakh) |

|---|---|---|

| Inert Shredder | 250–500 kg/hr | 45–90 |

| Eddy Current Separator | 1–2 TPH | 15–25 |

| Vibrating Sieve | 500–1500 kg/hr | 8–18 |

| Density Separator | 500–1000 kg/hr | 12–20 |

| Leaching Tanks | 5–10 KL | 10–30 |

| Filter Press | 30–60 plates | 12–25 |

| ETP (10–25 KLD) | — | 20–40 |

Larger plants benefit from economies of scale but need more safety mechanisms and higher power load.

| Plant Zone | Approx Area (sq ft) |

|---|---|

| Receiving & Sorting | 2,000–4,000 |

| Dismantling Area | 1,500–2,500 |

| Shredding Zone | 1,200–2,000 |

| Black Mass Zone | 2,000–3,000 |

| Hydrometallurgy Area | 4,000–6,000 |

| ETP & Utility Zone | 2,000–3,000 |

| Admin & Lab | 1,000–1,500 |

Most 1 TPD lithium battery recycling plants need 15,000–20,000 sq ft with proper fire and ventilation planning.

A professionally designed plant layout makes regulatory approvals faster and smoother. During registration and inspection, authorities typically look for:

Plants with scattered or overlapping zones face higher risk of rejections or delays.

The most expensive mistakes happen before the plant even starts running.

A client in Gujarat once designed the hydromet zone directly adjacent to employee lockers. During the very first inspection, officers complained about chemical fumes entering worker areas. The entire zone had to be reworked, delaying commissioning by over 40 days.

Thoughtful layout planning can prevent cases like these.

A smart plant layout offers long-term advantages:

Investors also prefer plants that show engineering discipline and safety-focused architecture.

Anyone can buy shredders, separators, or reactors. But only a well-planned layout can turn machinery into a reliable, compliant, scalable recycling plant.

A thoughtful layout:

If you’re planning a recycling plant, treat layout as your top priority — not an afterthought.

If you want expert guidance on plant layout design, machinery planning, and complete compliance support:

📞 +91 78350 06182

📧 wecare@greenpermits.in

Book a Consultation with Green Permits

A 1 TPD plant typically needs 15,000–20,000 sq ft including shredding, hydrometallurgy, and ETP zones.

Key machines include an inert shredder, density separator, sieves, hydromet reactors, filter press, and a multi-stage ETP.

Yes, lithium-ion batteries must be shredded under nitrogen or controlled atmosphere to prevent fire risks.

Black mass is a powder mixture containing lithium, cobalt, nickel, manganese, and graphite extracted after shredding.

You need SPCB CTO/CTE, Hazardous Waste Authorization, and recycler registration on the CPCB/BWM portal.